Seven Automatic Architectures

Turning small conceptual prototypes in big, bold and clean working installations

Customer:

Atelier Blumer – Accademia di Mendrisio

Challenge:

Help, inspire and guide the students in the design and implementation of the electronics and microcontrollers needed to make their projects work at full scale over two full semesters and a fixed deadline.

Year:

2016-2018

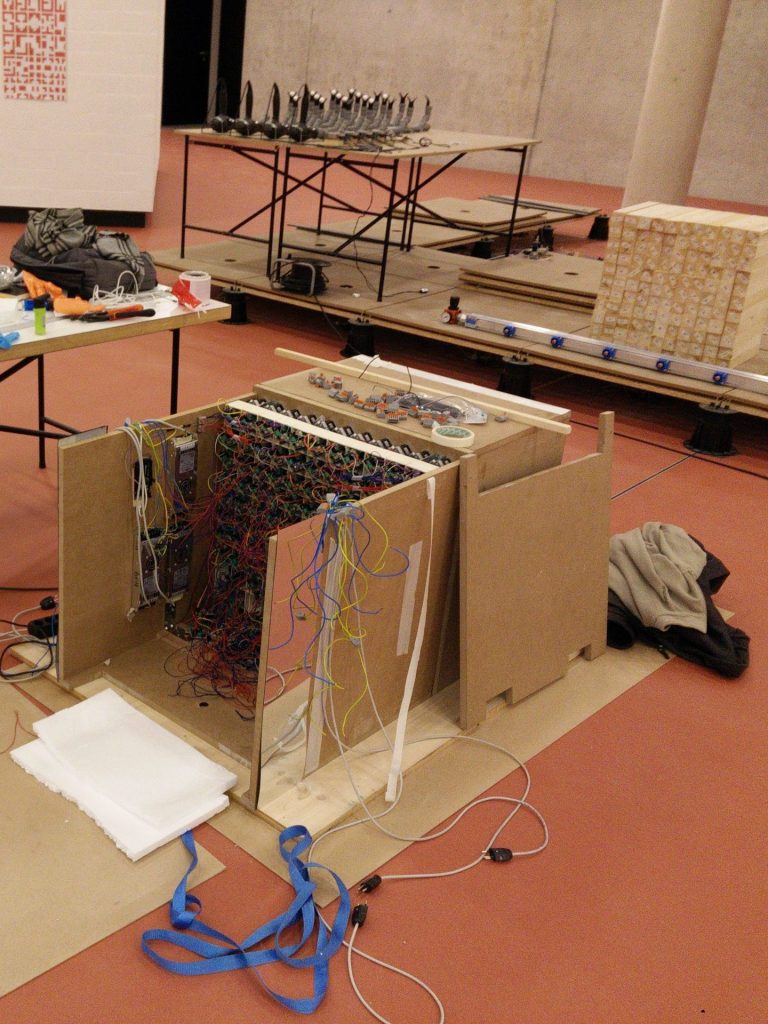

This was what I saw when I first entered Atelier Blumer

Welcome to Atelier Blumer

Towards the end of 2016, a maker and Arduino programmer working at Supsi asked Arduino if there was someone available to support the projects under development at Atelier Blumer inside the Accademia di Architettura di Mendrisio. He had no capacity left to help and therefore someone else was needed. The request was passed to me by one of my contacts at Arduino and I decided to give it a go.

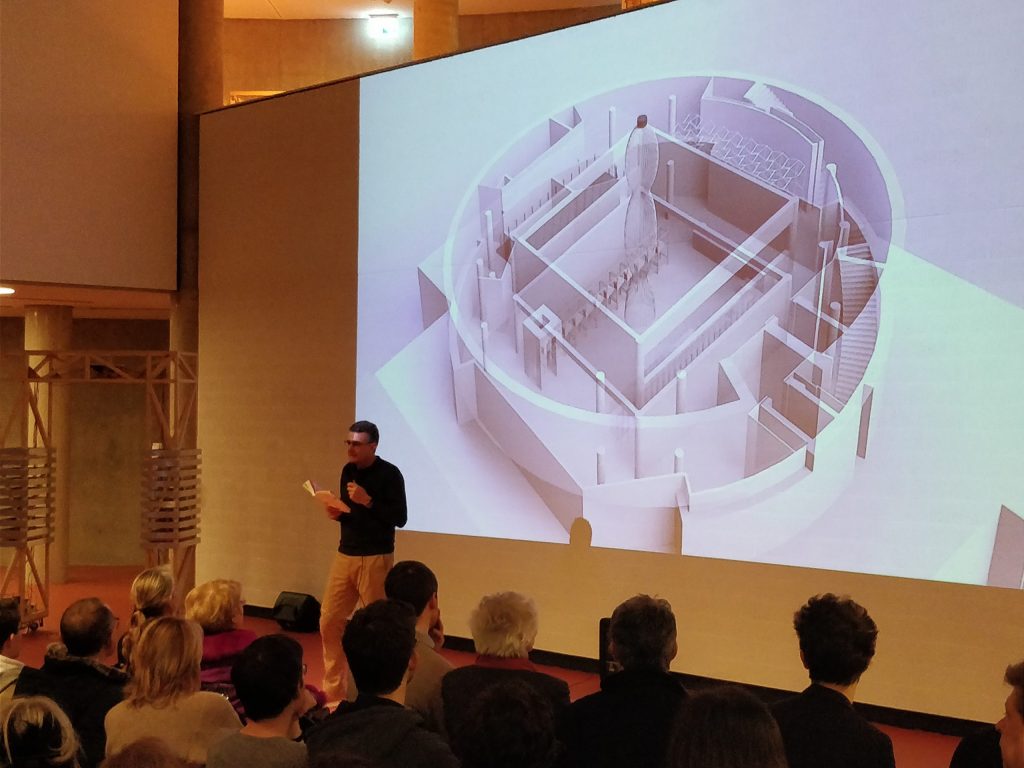

I took the train from Milano to Mendrisio (a Swiss town very close to the Italian border, 60 minutes from Milano by train) and I met the team at the Atelier to understand what it was all about. The semester was getting towards the end and a group of students were developing a series of small-scale prototypes that a jury would evaluate and select for the “big show” planned for the opening of the new “Teatro dell’Architettura” designed by the archistar Mario Botta and already in the making.

Each group was made of two students and the resources available in the Atelier were quite impressive: many 3D printers, woodworking equipment, some tools for electronics and the amazing trio of assistants: Tommy, Ettore and Matteo. Each had some specific skills and they were helping each group in the creation of their prototype.

The assignment was to create something that was both architectural and dynamic, related to the concept of limit. Surfaces were the first choice, but spaces and volumes were also present. Bringing the idea of transformation and time into architecture – something that was seen as static – was the big challenge that Riccardo Blumer threw on the table.

This was an opportunity that I had to accept, even if it meant commuting from Milano to Mendrisio, bearing the costs of transport, eating Swiss food and accepting very long working days (from 6.30 am to catch the train and returning home at 21.30). I gave my help to a couple of prototype designs and I was waiting for the development of the chosen project. On 22nd December 2016, all the projects of the Atelier were pitched to the judges’ panel.

Every prototype was showing a concept with creative solutions made to work on a small scale.

And the winner is…

Out of the proposed prototypes, the idea was to choose one, give a prize to the students and ask them to build a full-size version financed by a generous budget. What could possibly go wrong after all the efforts, creativity, ingenuity and passion put into every proposal?

Each team was waiting outside the Atelier, where the panel made by all the Faculty members was discussing what they saw when something unpredictable happened. The Head of the panel – Architect Mario Botta – said that each and every single project was so interesting, creative and worth being made in full size that it was not possible to choose just one: they were all winners. So he gave to the panel the task of finding new sponsors and fresh money to give a smaller prize to every student and finance all the projects. That was unexpected!

Two semesters to go

The exhibition and the grand opening of the Teatro dell’Architettura were set, planned and announced almost one year in advance: on the 8th of March 2018 the full-size architectures had to be in place.

The master plan was to use one semester to go from the small size prototype to a final working design, then the second semester had to be used to manufacture, test and place in the basement of the theater the installations. A generous budget was assigned to each group and I became part of the Team of assistants to support the students in their quest.

The Seven Automatic Architectures

Here is the list of projects and authors:

- Bridge

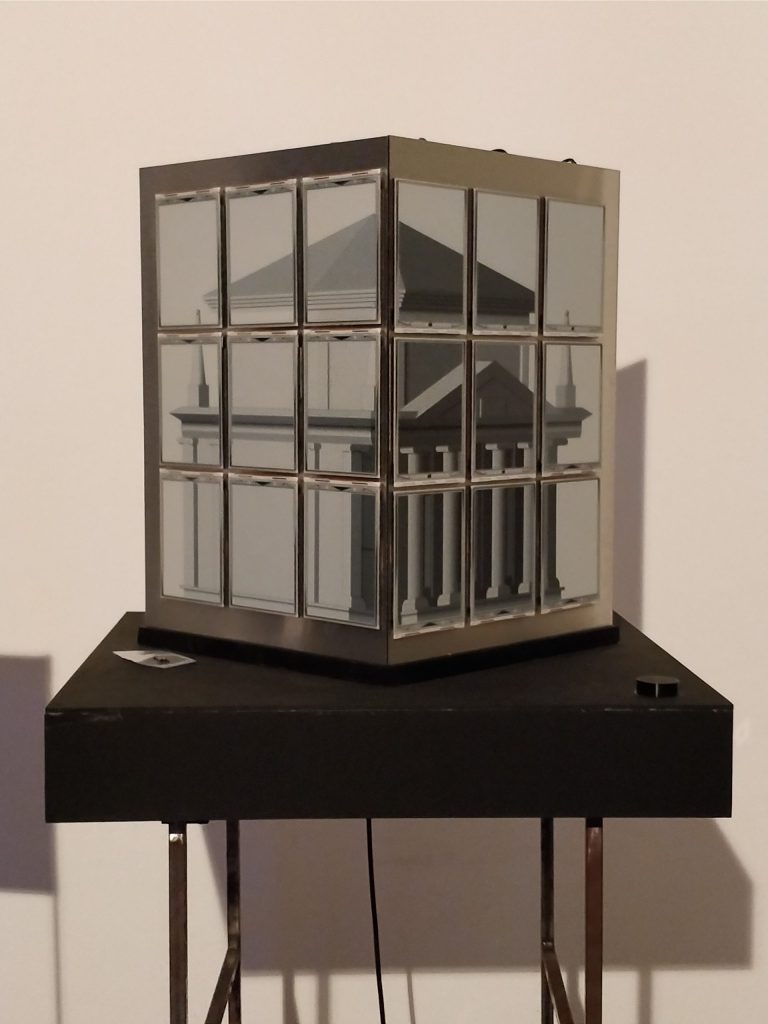

Stephen Okoh, Guglielmo Spada, Marco Vallario - Cube

Marco Pisano, Mattia Fornoni - Wall

Lorela Arapi, Stefano Clerici, Andrea Cappellaro - Echo

Rinaldo Makaj - Spider

Gael Chiappini, Flavio Guidi, Beatrice Dogliani - Door

Chiara Salmini, Milena Testini - Space

Georgios Voutsis

The Stepper Module

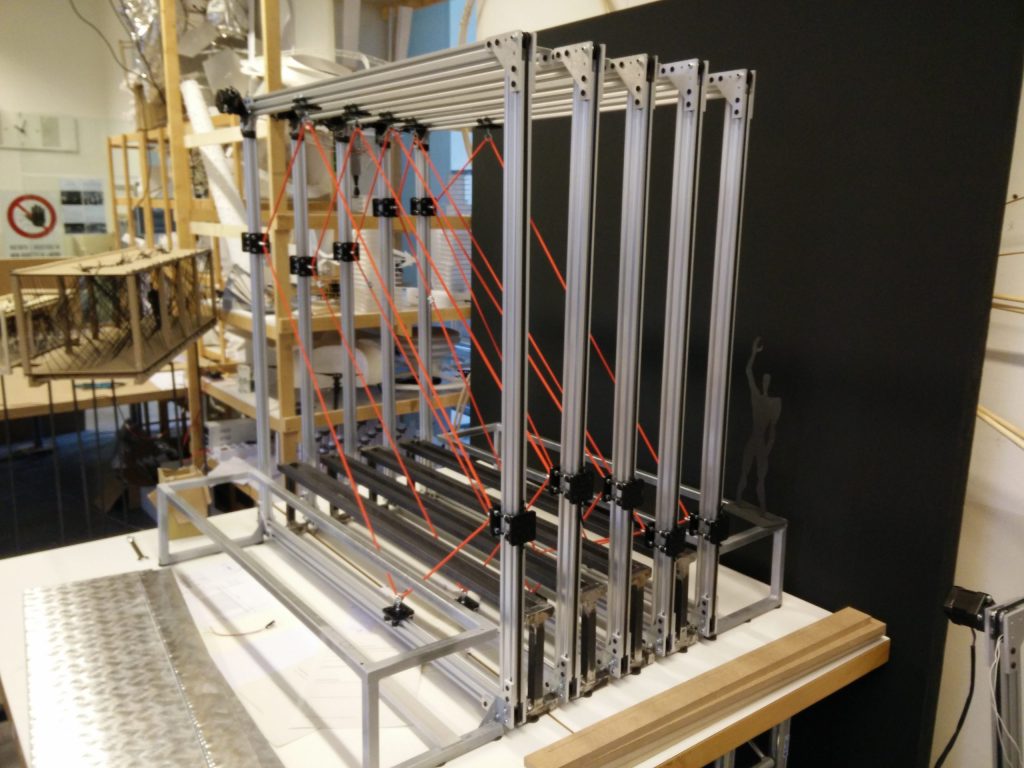

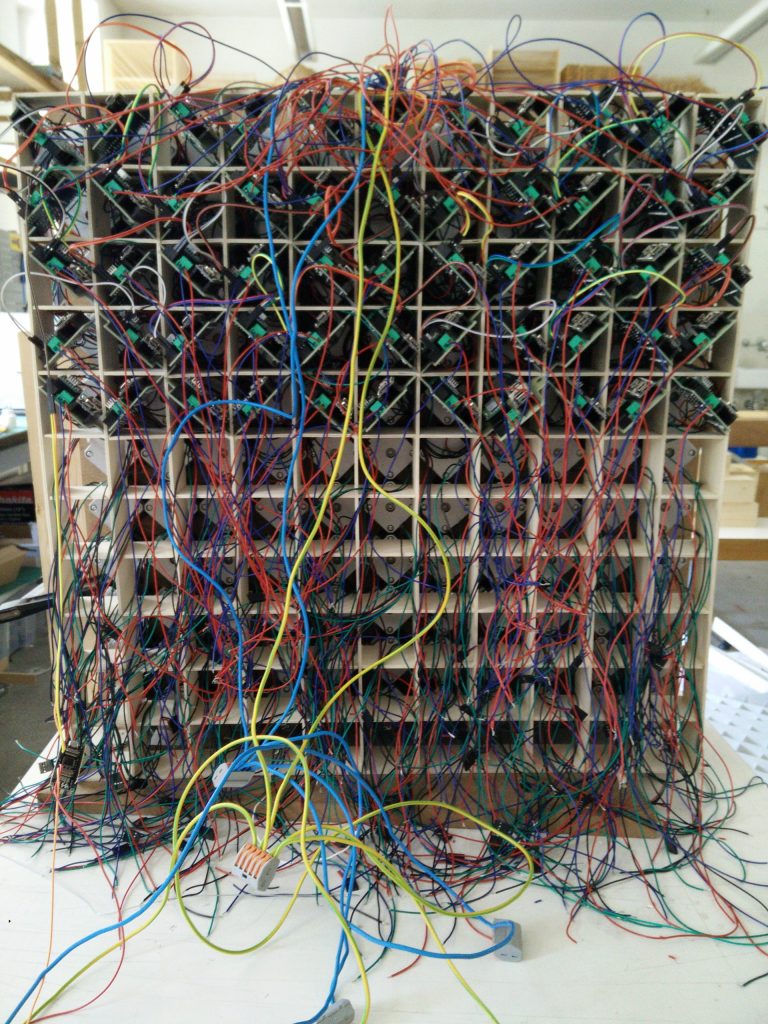

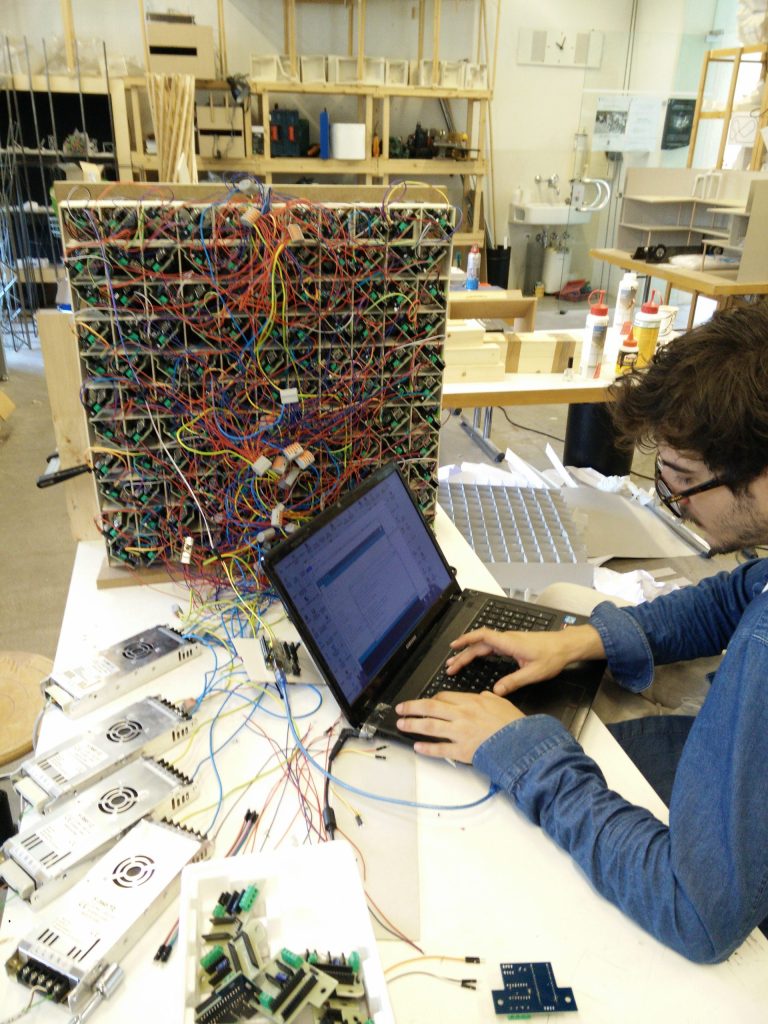

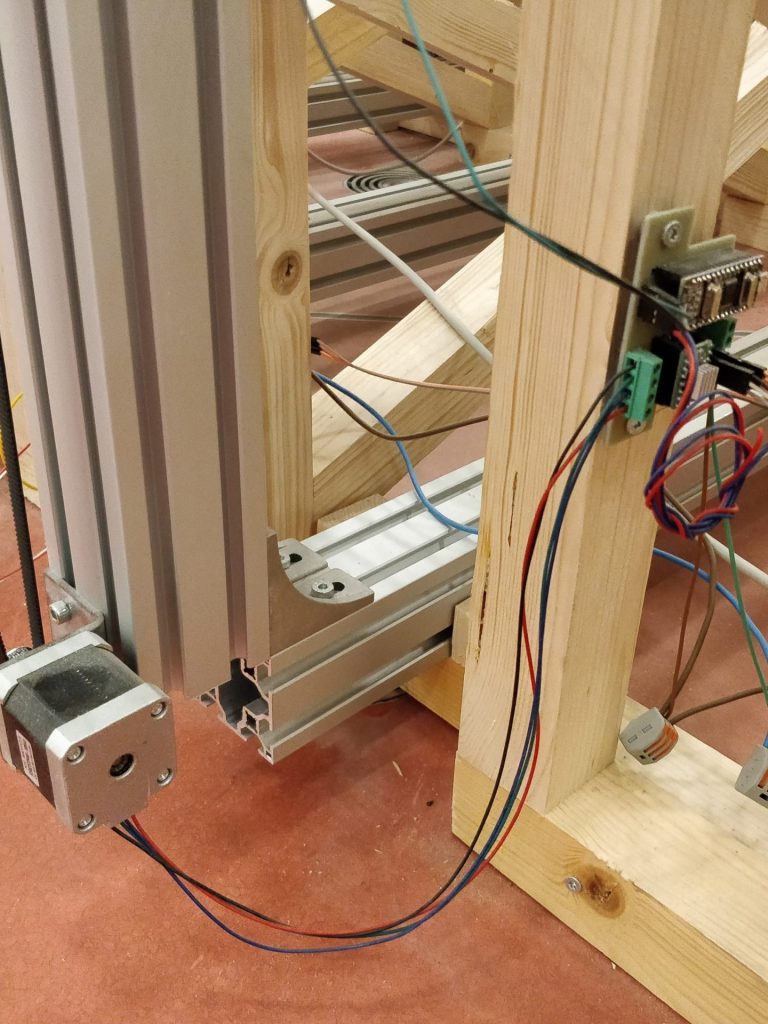

One of the seven groups of students that were awarded the chance of making their design in full size had to give up for personal reasons. The vacant space was then given to a single student that proposed a very interesting design. The concept he proposed was about a matrix of square columns, each one controlled by a motor. A series of algorythms would create different height maps that would create a series of “spaces”. A very intriguing concept, especially on the generation side: nothing was precalculated and every formula generated unique and (almost) never-repeating patterns. His plan was for a matrix made by 11 x 11 columns and this required 121 individual columns driven by a motor each.

Other designs required motors and the need for precise control made me choose stepper motors, the same used in 3D printers and for which I already had some experience.

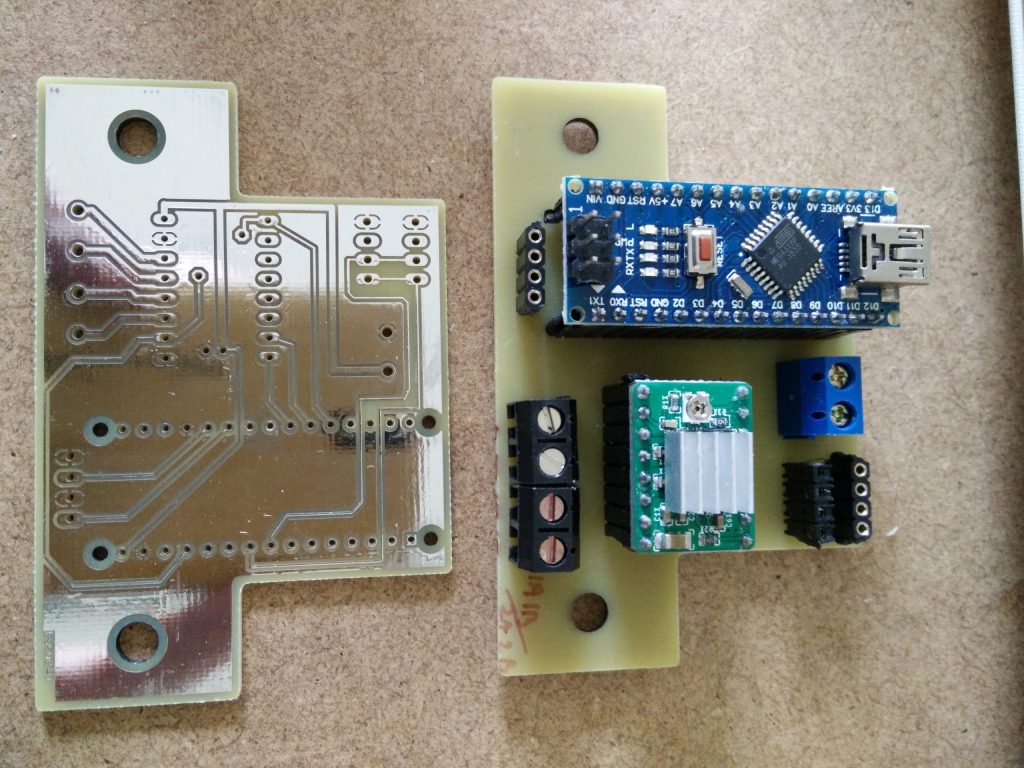

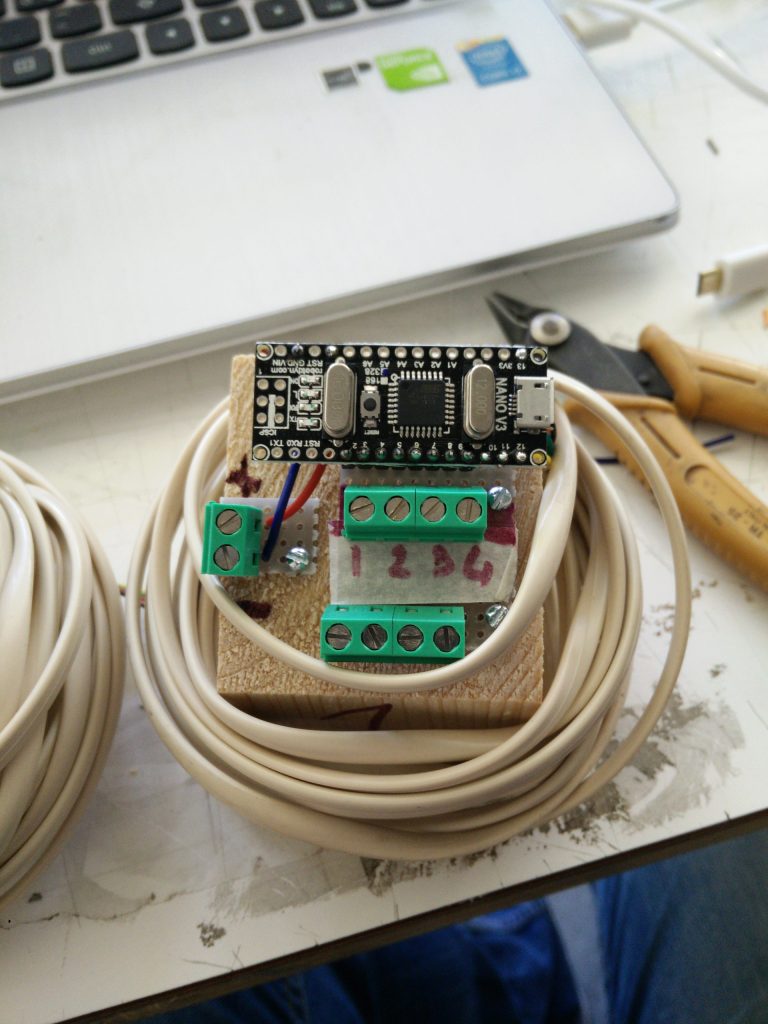

So many motors to control, however, were an impossible task for any type of Arduino board and this is why I applied the concept of distributed intelligence: each motor was driven by its own Arduino, placed on a board that had the Stepper driver module and all the connections needed for power distribution and communications. The Arduino Nano on the board was programmed to take care of all the movement parameters plus the zeroing through a microswitch. I designed a PCB that was fit for the SPACE design, but I also knew that it was a solution for Bridge and Wall. A simple I2C connection was the solution to control each board. This protocol allows up to 127 addressable devices and that made my solution fit for the 121 motors of Space. The module zeroed itself automatically at power up and then kept track of the absolute “position” of the motor. Sending the new position to the module was what it was needed to move the motor.

The five test boards were OK and therefore the Atelier decided to source a massive amount of PCBs, stepper motors, drivers and Arduino-compatible NANO boards.

I developed the board software so that it could autonomously manage situations like stuck columns, mechanical failures and other issues: resiliency was one of the requirements. The protocol was bi-directional, with the controlling unit that was able to interrogate each module about its status (moving, zeroed or idle). The speed of the I2C connection was enough to send the position to all the motors in roughly half a second and this made all the motors of the matrix start to move at the same time.

The hardware design had two Data pins exposed, useful for sensing switches or other signals.

My little board made the design of some of the projects much easier and I was really satisfied with its performance. Once the code was properly developed and debugged, the movement of any number of stepper motors was just a matter of sending out numbers on the I2C connection. Something that an Arduino was more than capable of doing.

The scalability of this approach was ideal, but still, it required a lot of soldering and testing: each board had several components and roughly 60 solder joints. The Nano boards came with unsoldered pin strips and that required another thirty pins to solder. Any cold joint and the board ensemble could fail. To allow serviceability, everything was with male and female pin strips.

The Space student gave a hand in the soldering and assembling process, but being totally unaware of electronics and its rules, he made quite many mistakes in the first assemblies (reversing polarity) and he needed some practice before his soldering abilities were good enough.

One design, many challenges

Going from a small-scale conceptual prototype to a full-sized installation was something that not all the students understood in its full complexity. Things that work on a small scale might pose almost unsolvable challenges when scaled up. Each group had to validate their concepts before they were able to proceed with the design to be built in the theatre.

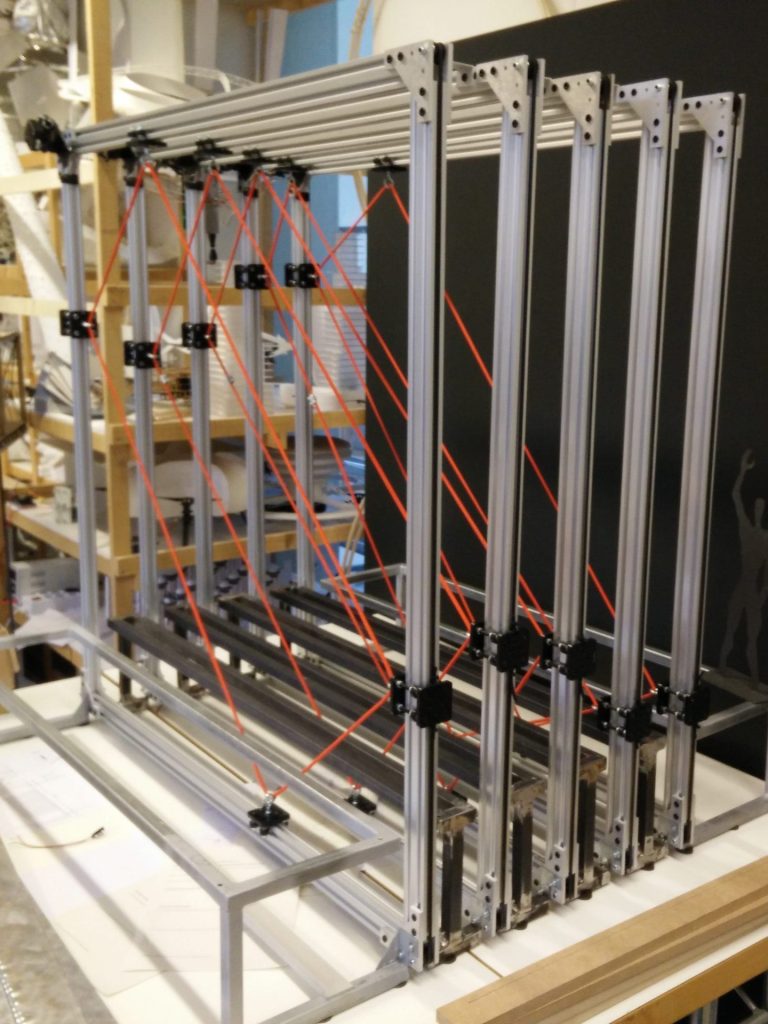

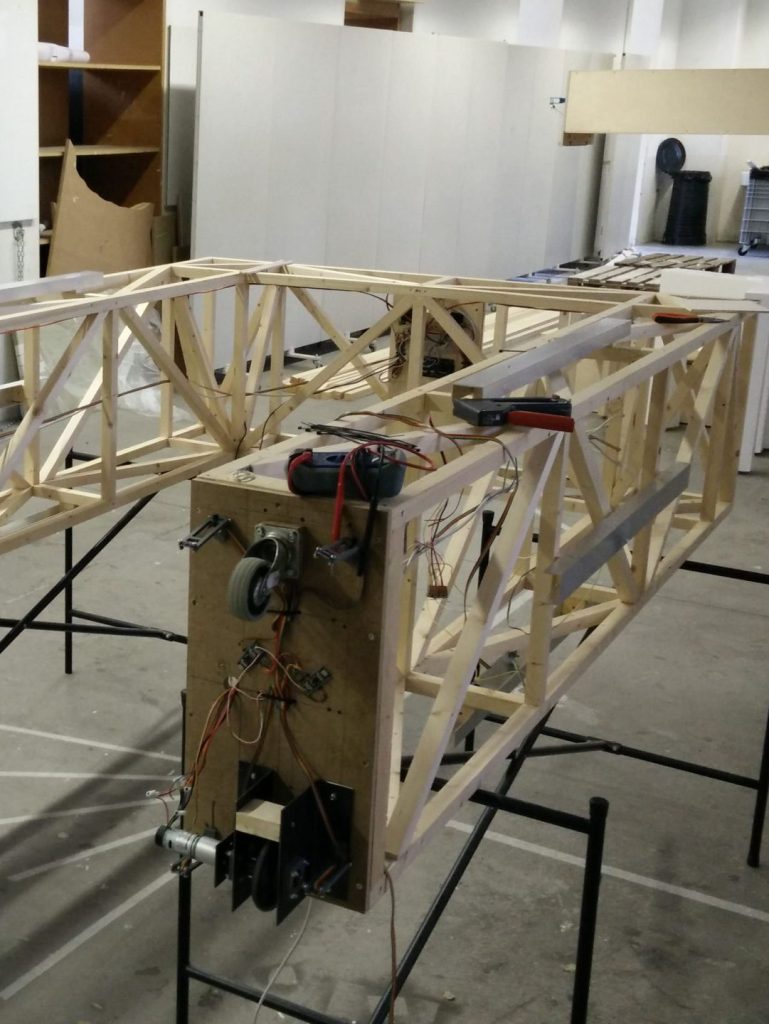

Bridge needed to develop a system of carriages capable of moving the rope and creating a parallelogram of the expected shape.

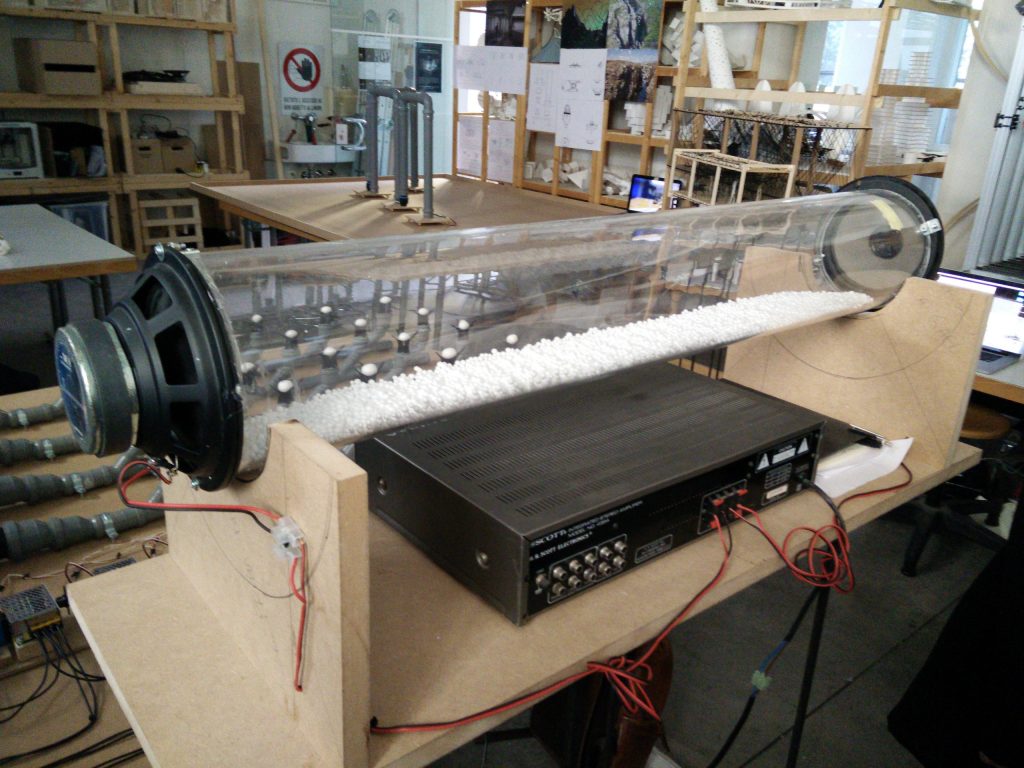

Cube needed laminar flow of air on a volume that had never been tested before, so it was a really ground breaking design.

Wall had three interesting issues: the chemistry of the soapy bubble-making liquid, the physical system to create the bubble and how to detect if the bubble was there.

Echo was all about air flow and air valves. On a small scale it was doable, but the scaled up design had so many air valves that controlling the whole system and feeding enough air with proper pressure and flow became very hard to achieve and control in a predictable way.

Spider created geometries with actuators that deformed triangular shapes in a three-dimensional structure. Sometimes the result was not possible and the structure broke the joints to release the force. That project was particularly impressive because it clearly transmitted this “unstoppable” strength in its movements.

Door was somehow less critical but still required some awareness of the surroundings to avoid hitting people or tripping on obstacles.

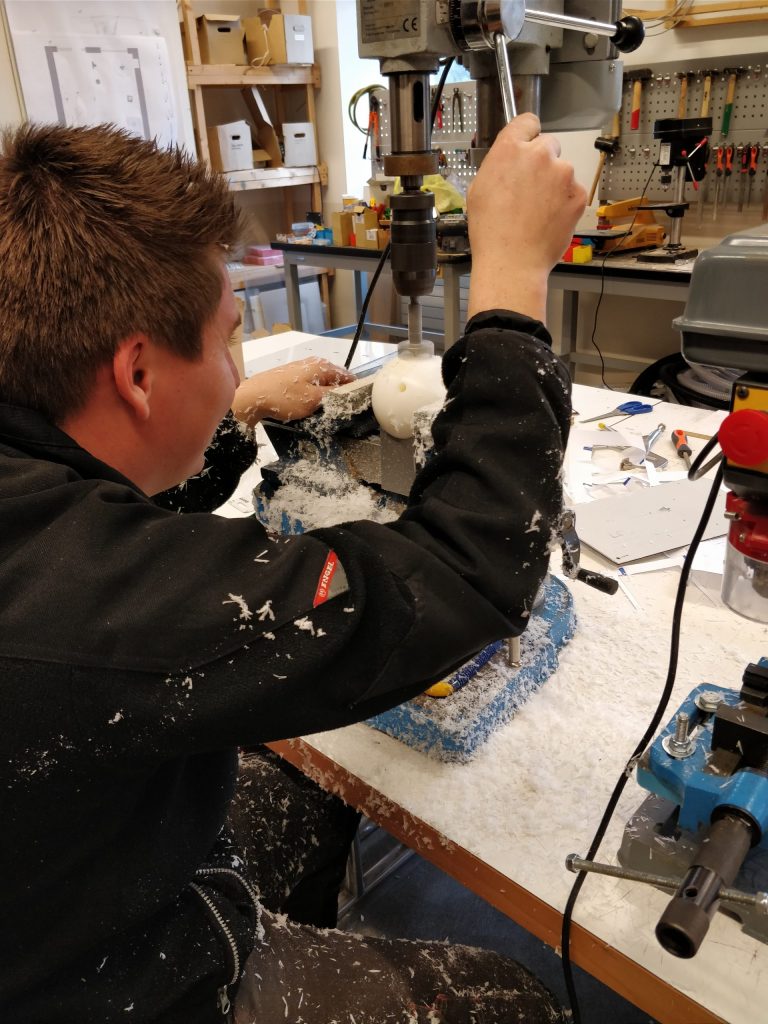

Space was just repetitive in the assembly, so every connection, every solder joint and every wire was a potential point of failure. Moreover the choice of the materials: NEMA17 stepper motors, threaded bars and wood columns into a 12mm MDF cabinet brought the overall weight to over 150 Kg. A nightmare to service and move around.

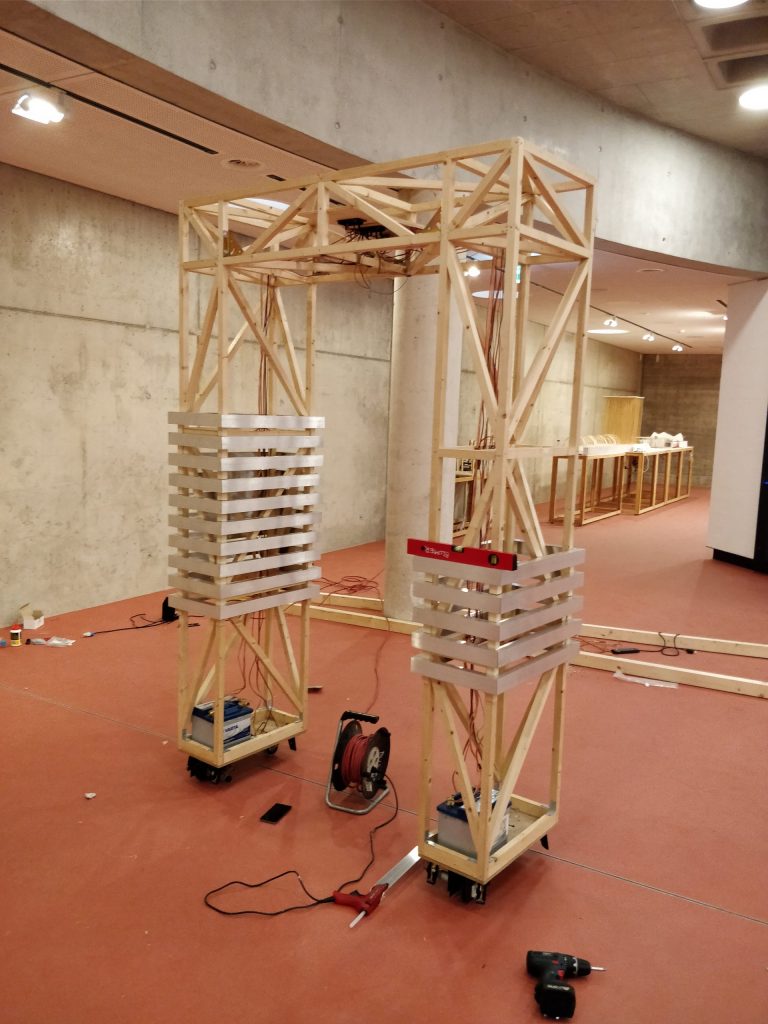

Phase two: build in place.

At the beginning of the second semester, the theatre was still under construction, but the overall structure was finished. This meant that soon we had access to the basement to start the construction of the various installations, or at least the ones that were too big to be built somewhere and then moved into the final position. Namely Wall, Bridge, Matrix and Cube. Space was very heavy, but its size allowed it to be moved on a transpallet. The floor of the basement was made of very expensive and technical epoxy. It had hardening times and our presence in the basement with tools, metal and wood parts were seen as a danger for the proper outcome of the flooring. We then took precautions with protection panels and designated areas for tools and spares.

All the designs had to rely on simple materials: wood and aluminium profiles, plus the electronics and the parts that were essential for the project.

I was involved in the making of Space, Matrix and Bridge, plus some support to Door and Wall. Cube and Spider relied more on metal and mechanical designs, getting help from the other assistants in the team. The task was huge and the deadline was quite tight. Each team worked 5 days a week in various areas of the Accademia, turning emptied classrooms into dedicated workshops. Sometimes tools like Miter Saw were passed from one team to the other because there were just a couple available. The usage of wood slats was massive and MDF panels were the second most used raw material.

The months passed rather quickly and the hard work was carried out starting from August 2017. The Accademia was deserted by regular students and this is why the classrooms were available for the temporary workshops of the teams.

The DIY supplies shop of Mendrisio had a serious increase of its turnover thanks to the large quantities of wood, MDF and small metal parts. The aluminium profiles were bought from a supplier after a research for the best prices and delivery times.

The soap mix was initially developed by the students following some internet recipes, but the one that was working best was the very first one concocted and sadly they did not write down the percentages and they never managed to get the same long lasting effect. When the time for the experimentation was all gone, they had to switch to commercial soap bubbles mix.

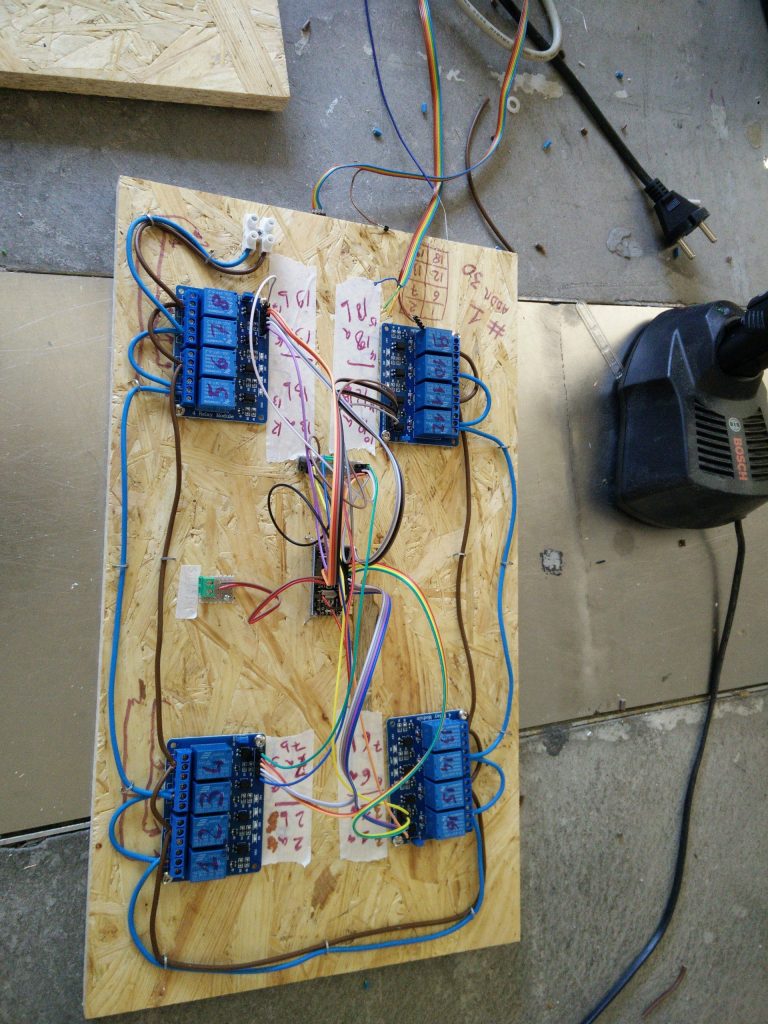

I spent quite some time trying to make the Matrix project to work, but the number of tiles with a hole, a ball and an air nozzle was so high that we lost reliable control of the system on many levels. The electric air valves – two per each nozzle to have “two levels” – generated spikes that reset the Arduino controllers, so my coding job became a nightmare. The cables driving the valves and the shielded wires connecting the Arduino boards crossed in many points and there was no way to avoid these intersections. On the air flow side, we learned that every valve had to be regulated to get the ping pong balls at a similar level, but the airflow changed if the order in which the valves were triggered changed. Last but not least problematic was the amount of air consumed: the 5000 liters compressor was enough to feed for no more than 20 seconds a pattern with the 50% of the valves open. As a result of all these issues, we had to redesign the electronics and the patterns: a single Arduino Mega was driving directly only one of the valves of each nozzle offering just a single height for the pingpong balls. We also selected the patterns that did not exceed the 50% of the 48 available tiles. Matrix was saved.

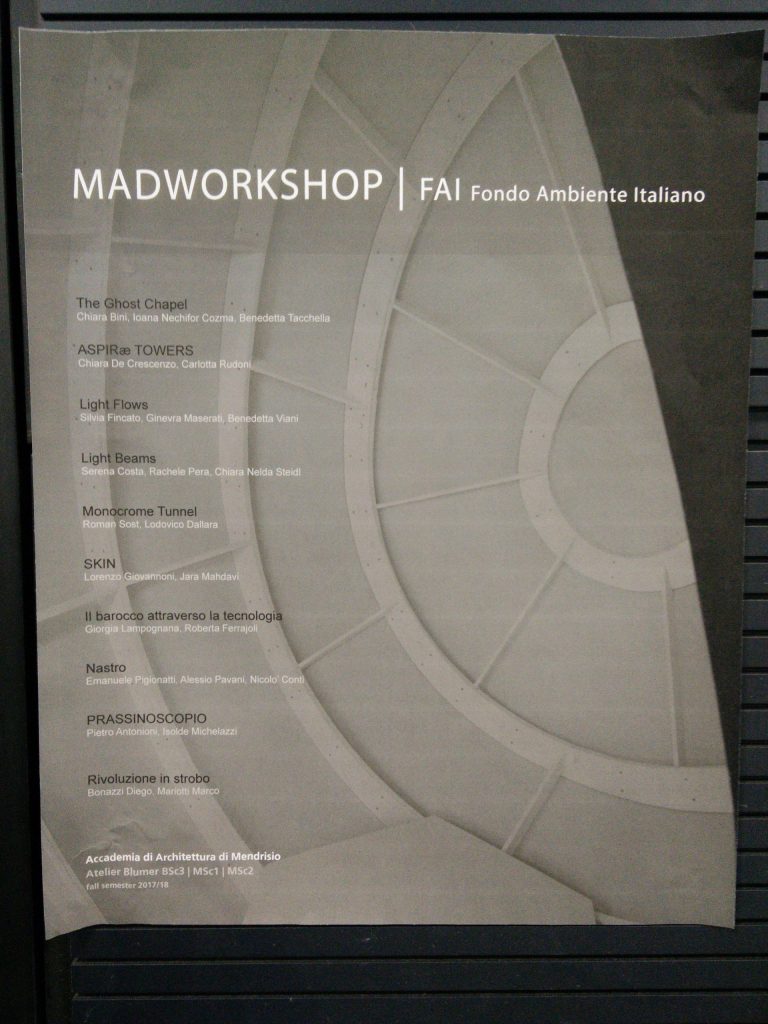

The Atelier Blumer never rests

When the students of the Seven Automatic Architectures entered their third semester in a row, a new group of students started a new Atelier and Riccardo Blumer managed again to find a theme and a sponsor. In this case the purpose of the new Atelier was to reinterpret the baroque spirit of the fourteen chapels on Sacro Monte near Varese. All the work done in the semester would be on display in a special exhibition at Villa Panza in Varese, a 18th century mansion, whose windows look out on a magnificent Italian garden, hosting one of the foremost collections of contemporary American art, as well as international exhibitions. This atelier was made possible thanks to Mardworkshop and FAI.

Amazing results

The variety of the projects was again amazing and this time electronics were very limited and I got involved in just one design.

The carousel of pictures shows the variety of the designs created and a few of them were truly amazing.

My effort was all focused on the e-paper display structure, showing different elements with a perceived depth thanks to a careful render made to be displayed on two groups of screens properly angled. The change of images had to be synchronized and the electronics of the e-books used weren’t really hack-friendly.

Among the various installations, these were the ones I liked most.

An installation used the stroboscopic effect to recreate a whole chapel out of a single rotating slice of it, demonstrating how symmetry was part of the design.

Another installation recreated the effect of the green vegetation forming a tunnel and biasing the colour perception.

A third one used virtual reality to let the viewer experience the concept of a voyage between the chapels.

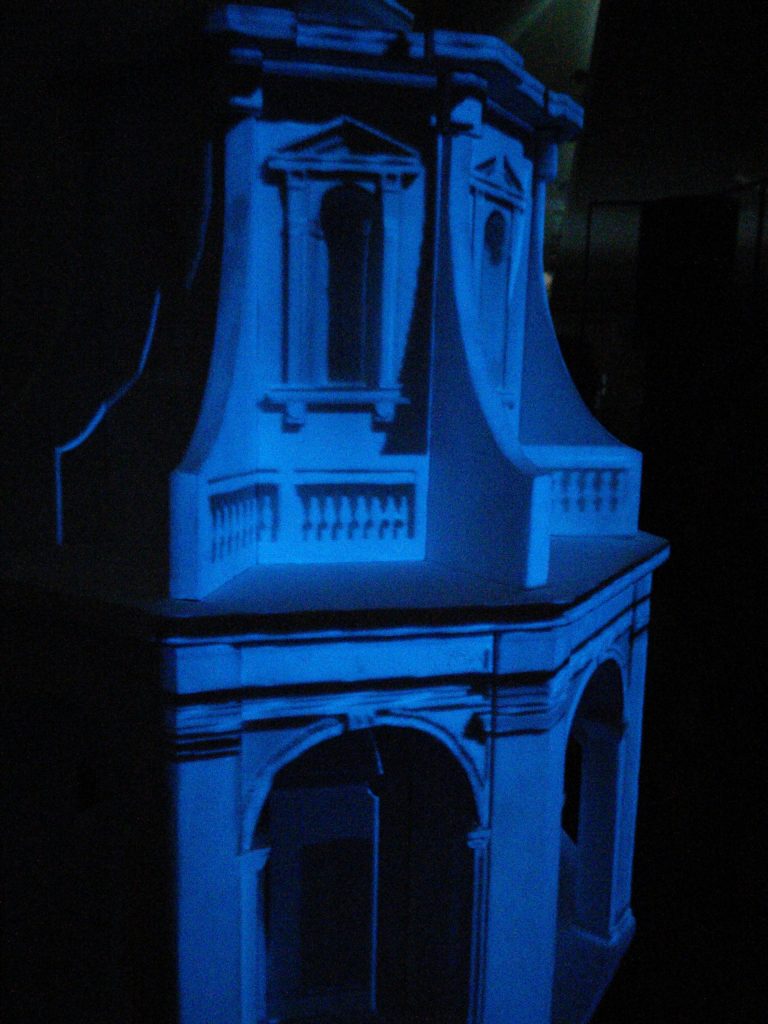

A really creative one used a flat model of a chapel on which fluorescent paint was charged with a colourful projection. When the projection was stopped, the paint made the flat surfaces look like the rich detailed original rich baroque architecture.

8 March 2018

After many months spent planning, making, testing and refining, the seven automatic architectures were ready to be shown to the world. The Teatro dell’Architettura was finished and a big event was organized to mark the start of a new era for the Accademia di Mendrisio. Mario Botta was the host of the event and Riccardo Blumer, as Dean of the Accademia, was one of the speakers. All the students, the assistants and the faculty members were attending. Downstairs all the devices were ready to show off their functions and peculiarities. This video shows some of the installations and was shot on the 8th of March 2018.

The end?

Again, Riccardo Blumer made something special by bringing the Curators of Biennale Architettura 2018 in the Atelier. “FREESPACE” was the title of the 16th International Architecture Exhibition of Venice, curated by Grafton Architects. The opening was set on May 26th 2018, just a little more than two months away from the event that just happened. The curators were very impressed by the installations and their attention was drawn by Wall and Space. Basically, they wanted those two installations in Venezia and that was an invitation that the Accademia couldn’t refuse.

You can find the full description of this new project in “Space @ Biennale di Venezia 2018“