Digital Fabrication

From bits to atoms and from ideas to reality: these are the technologies that make a Fablab a very special place

From bits to atoms

This is the claim of maker spaces and Fablabs, where a set of machines get digital input as files and turn the data into milling paths, 3D printing shapes or Laser cutting paths. Almost all the objects fabricated are designed digitally with specialised software in 2D (for laser cutting) or 3D (milling and 3D printing). Then a series of other machines allow further modifications, assembly and finishing. Depending on the maker space equipment, the additional resources may include woodworking, metal shop, vacuum forming and resin casting.

The usage of the digital fabrication machines and the additional equipment is subject to training and the access may be controlled by membership. Each device has its degree of difficulty in the preparation of files and set-up. Robot and CNC milling are the most complex and laser cutting is the easiest. 3D printing is often considered easy, but size, complexity and choice of materials vary from one technology to another. The high-end Resin and Nylon Powder are usually unavailable in maker spaces, where Plastic FDM printers are the norm.

A Maker knows them all

Using the tools of digital fabrication is part of Maker’s skills. I was involved in Italy in the birth of more than one maker space and Fablab; I went through various pieces of training and I was a trainer myself. Here in Dubai, I was the Fablab Manager of the in5 laboratory, of which I also took charge of the renovation and restructuring to host new machines and better their usability. In the 15 months I was there, I revamped the 3D printing capabilities and added some Arduino training. I also was there while the Covid lockdown stroke and I had to do “miracles” to keep the lab doing its function, producing materials and kits, when everything was closed and only supermarkets were open.

For a Maker, the lab is this happy place and I took the time to make my space there an intriguing and brain-stimulating place, with a collection of things to inspire the students. You can read my message to the students and faculty here.

Due to the nature of this activity, my task went from create kits, “mass producing” some parts and engineering solutions suitable for the students to straight production of a student’s design, without intervention.

The initial approach of many students was “let’s 3D print” straight from the CAD software – typically Rhinoceros – but often sizing wasn’t their best choice: they had difficulties with the relation between screen and real world. It is a typical problem: with many CAD apps everything is relative and therefore you don’t worry much about measures, unless you are using a mechanical CAD where measures are basic parameters for constructing geometries.

For me this is something natural as I started doing CAD modeling for 3D printing and I was perfectly aware of sizes and build volumes. A Caliper is part of my desk tools, together with pens and rulers.

Save Your Ears

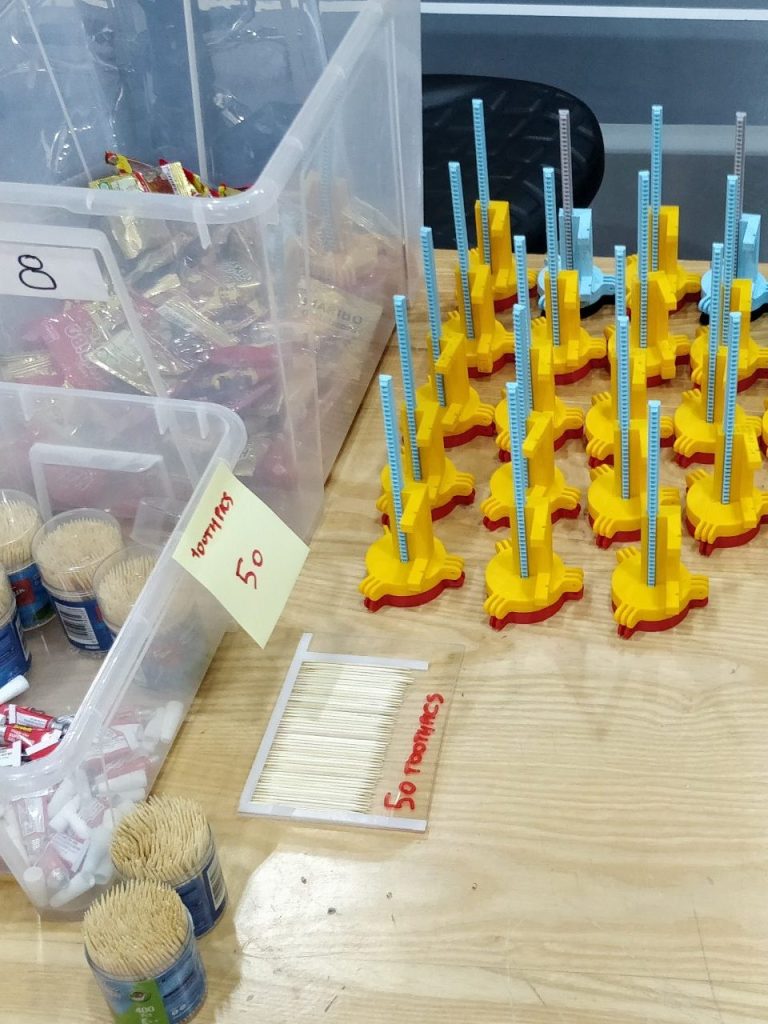

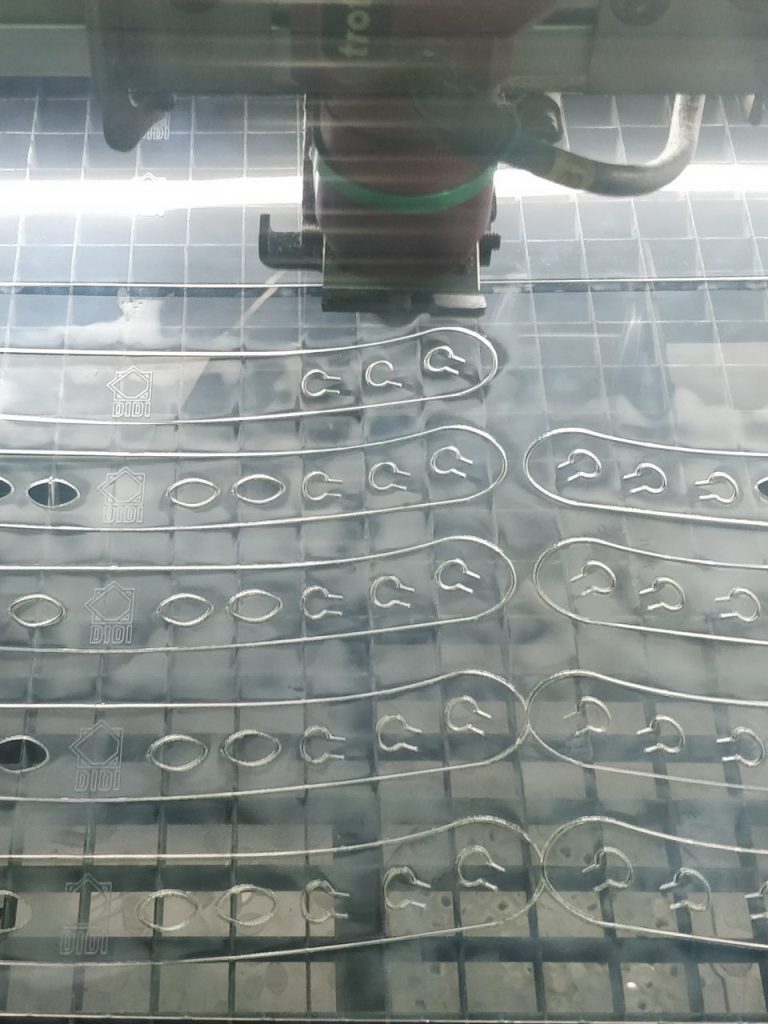

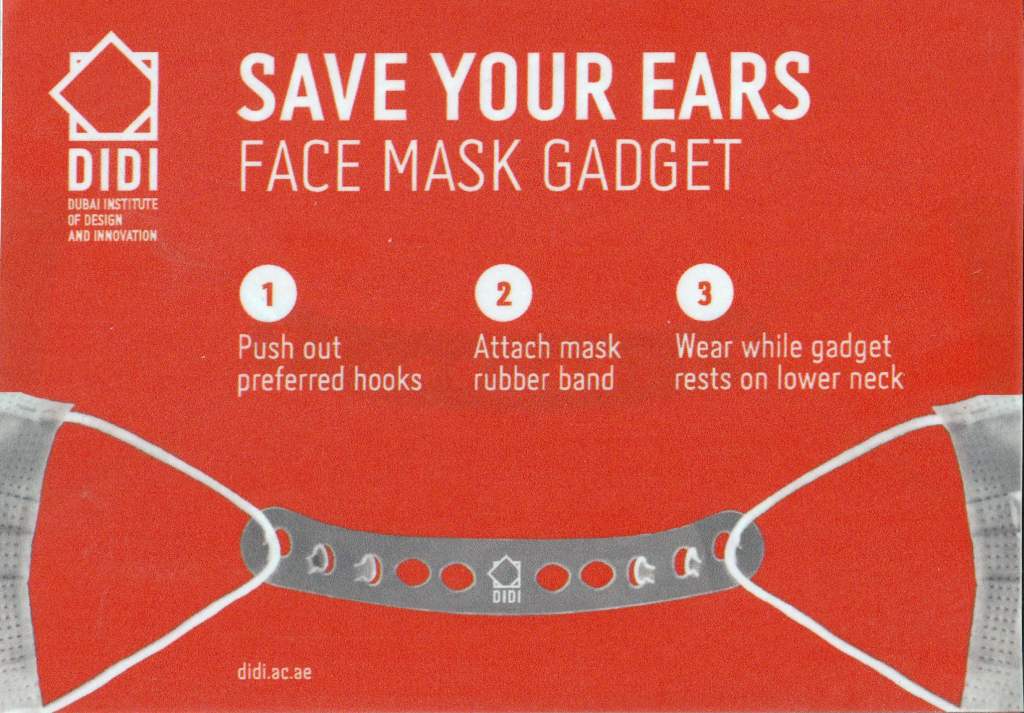

One interesting activity, done at the very beginning of the Covid Lockdown was the design and mass production (some thousands) of the Save Your Ears PetG strap. It was a simple thing that allowed you to hook the bands of your facemask away from your ears, with three different settings. It took me some iterations to find the most comfortable and fast to lasercut design, but at that time there were no such things easily available and it was an immediate success.

DIDI made a desk display with around forty pieces each and it was distributed in all the D3 (Dubai Design District) public spaces with a 100 pieces refill. Even better, the PetG used was a leftover from another activity, so the whole initiative was done with no material costs. Another example of ingenuity turned into something useful thanks to the digital fabrication tools available in a properly equipped maker space.

Why experience is important

Ever wondered why some projects turn out beautifully while others fall apart? The key is often in understanding the right fabrication methods. There are so many machines available – the right choices make the difference between success and disappointment.

Imagine you envision a delicate piece of jewelry with intricate details – 3D printing might seem like the obvious choice. But an experienced maker might suggest laser cutting with metal for greater durability and a more refined finish. Or perhaps your design features interlocking parts – knowing the tolerances of each machine and how materials react to different processes will determine how well those parts fit together.

I help you balance budget, timelines, and desired finish to choose the fabrication method that perfectly suits your project. And it’s not just choosing the right tool – it’s knowing how to adapt your design to maximize the machine’s capabilities and avoid costly errors. My years of experience mean you get the best guidance on your project from day one.

If you are an educational institution, I can consult with you to set up a fabrication lab that aligns with your curricula and budget. I’ll suggest effective solutions and the right software to manage bookings and resources. Plus, I can offer insights on safety protocols, maintenance routines, and curriculum integration, maximizing the lab’s potential and ensuring students get the most from this hands-on learning environment.

Got a project in mind for your next fabrication laboratory? Let’s discuss the best way to bring it to life.

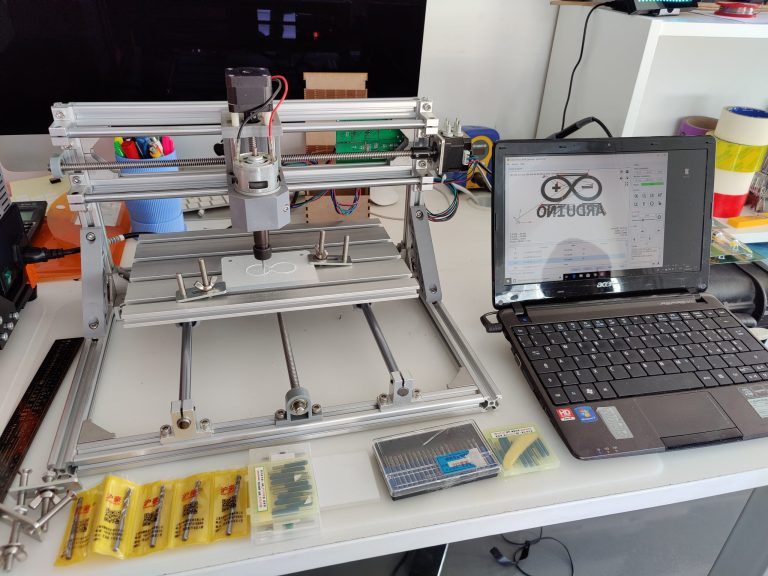

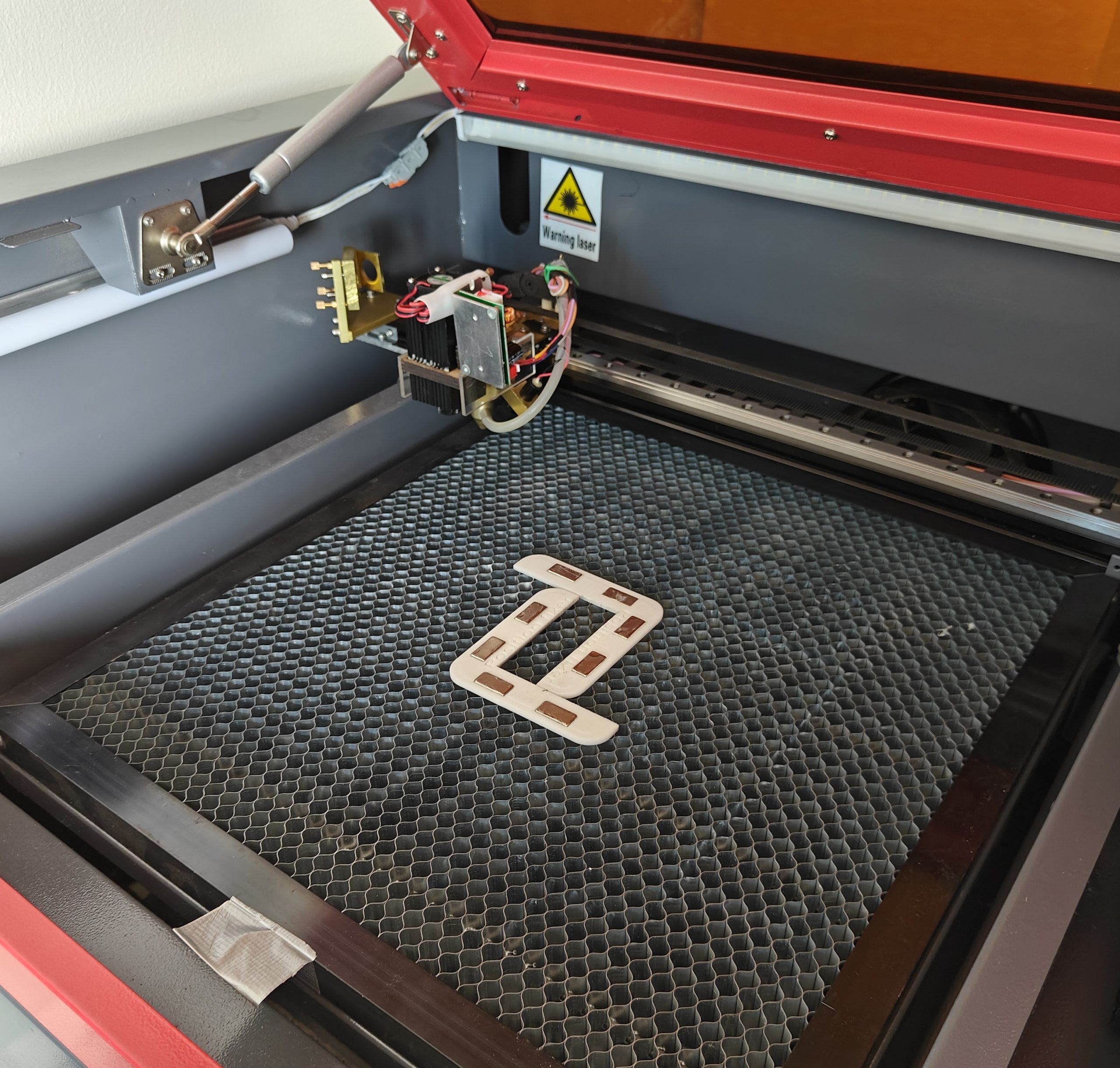

Now with a home lab

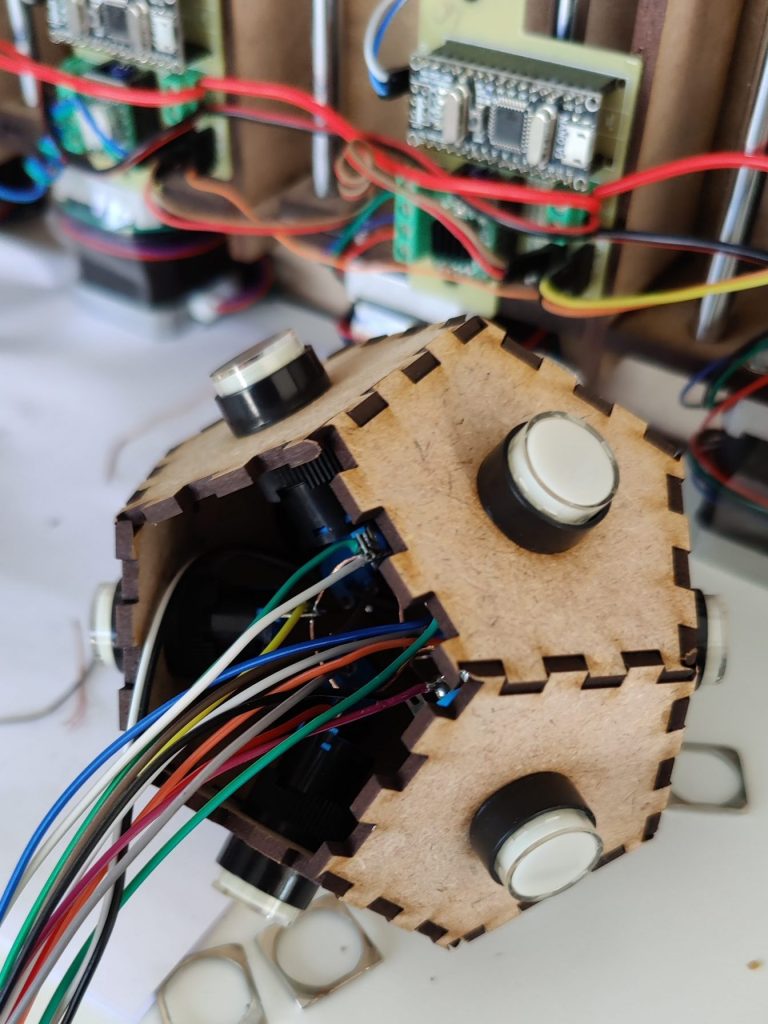

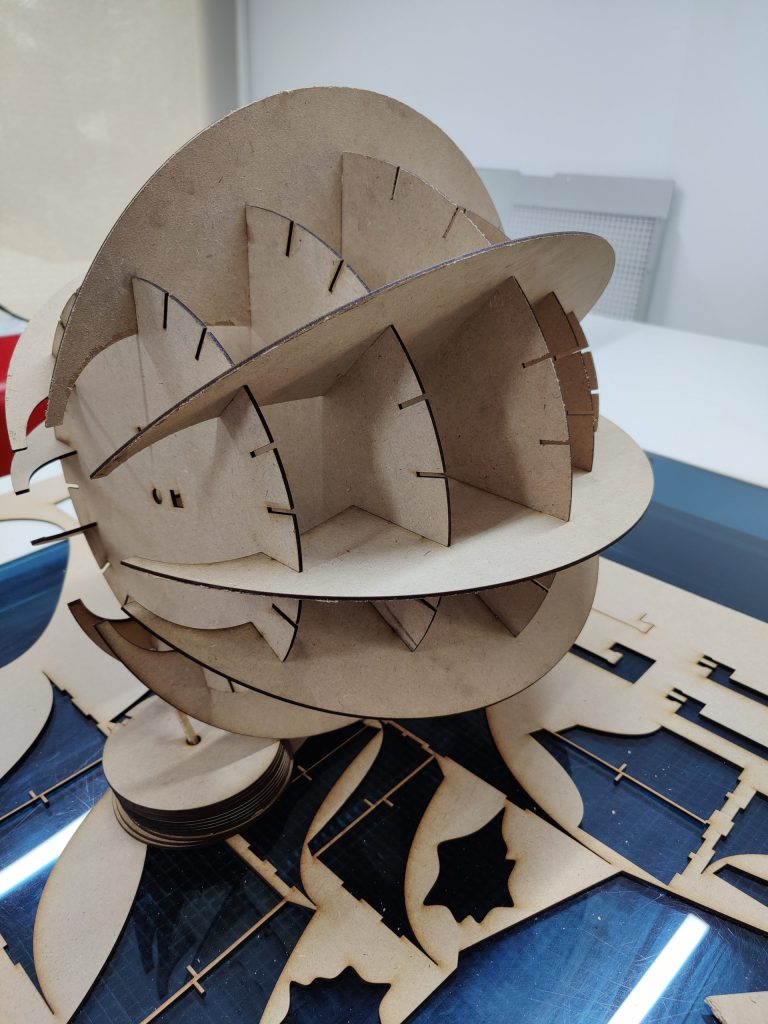

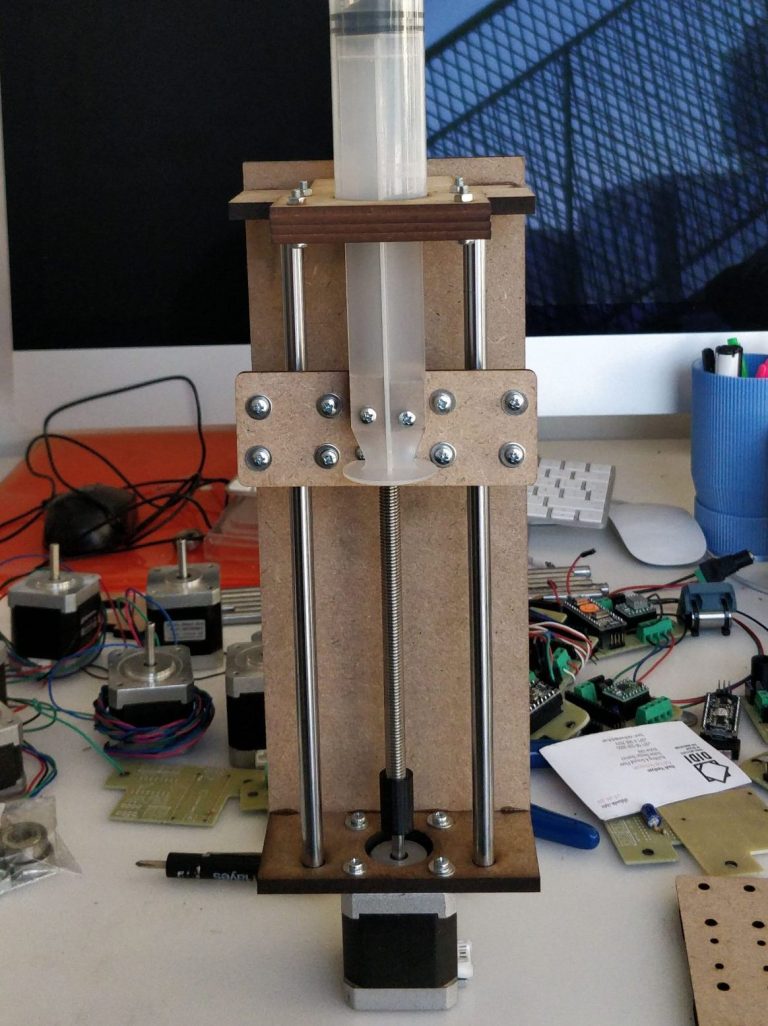

The passion for digital fabrication and for the tools needed to “make stuff” never left me. My home lab is now a testament to that passion, a symphony of buzzing 3D printers, the precise cuts of a laser, and the intricate movements of a small CNC machine.

Surrounded by electronic components and tools, these machines empower me to go beyond the theoretical, to transcend the confines of a sketchpad. With them, I can design and make small installations, pieces of art, and electronic devices that defy expectations.

The laser cutter’s potential already expanded with modifications to work with a wider range of materials, and upgrades for steel etching and marking are next in the pipeline. As a painter is always searching for the right brushes and colors to find new textures and expression, a maker is always improving his fabrication capabilities, adding new tools and fine-tuning the existing ones.

I’m ready to turn your vision into something tangible, something you can see, touch, and experience. The fusion of electronics with my fabrication skills allows for interactive installations and uniquely functional objects. Have an idea in mind? Let’s discuss the possibilities and turn your vision into reality.